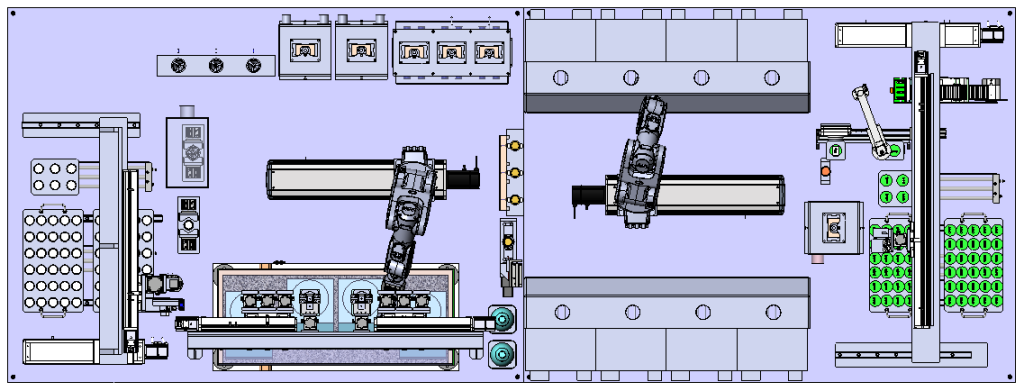

Gold automatic pouring system

Categories: Assembly、Collaborative robots、Testing、Vedio

Equipment introduction

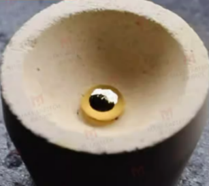

This project uses manual loading, and the system automatically completes the processes of melting, visual inspection, mold pouring, ignition, cooling, cleaning, weighing, oil pressure, unloading, etc. The difficulty of the equipment lies in the judgment of the melting end point, and the material loss caused by the long melting time should be reduced. And the mold pouring speed and angle control during the mold pouring process to prevent water ripples and affect the appearance quality of the product. Finally, various parameters of the ignition process should be controlled to ensure that the mold reaches the optimal casting temperature.